I learned to engrave on a Roland EGX-400, and it has taught me a lot. I enjoy messing around with the direction that the path takes and seeing the visual effect reveal itself on engraved brass or aluminum - I think there's a lot of opportunity to use the subtle drag lines to enhance an engraving.

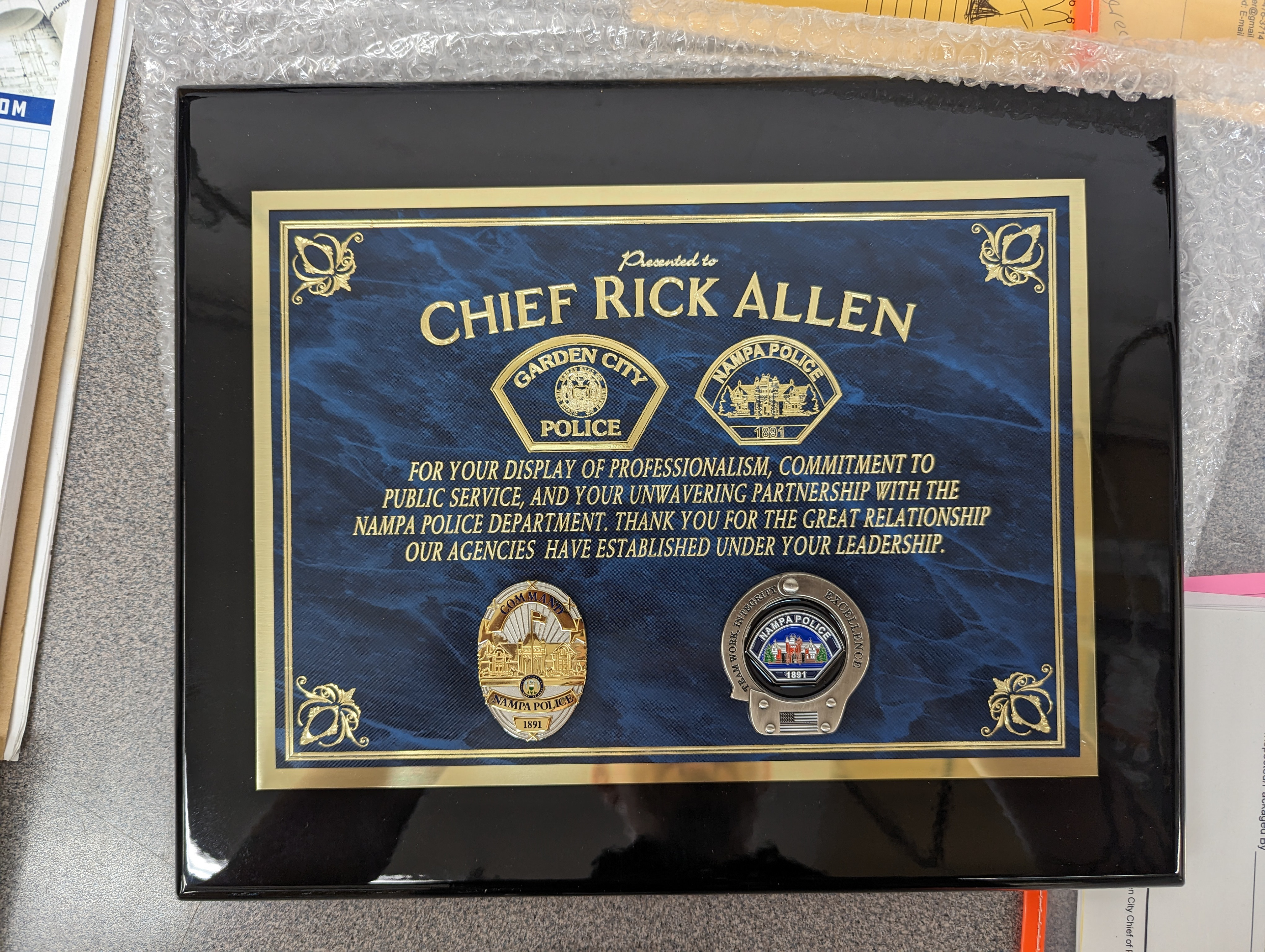

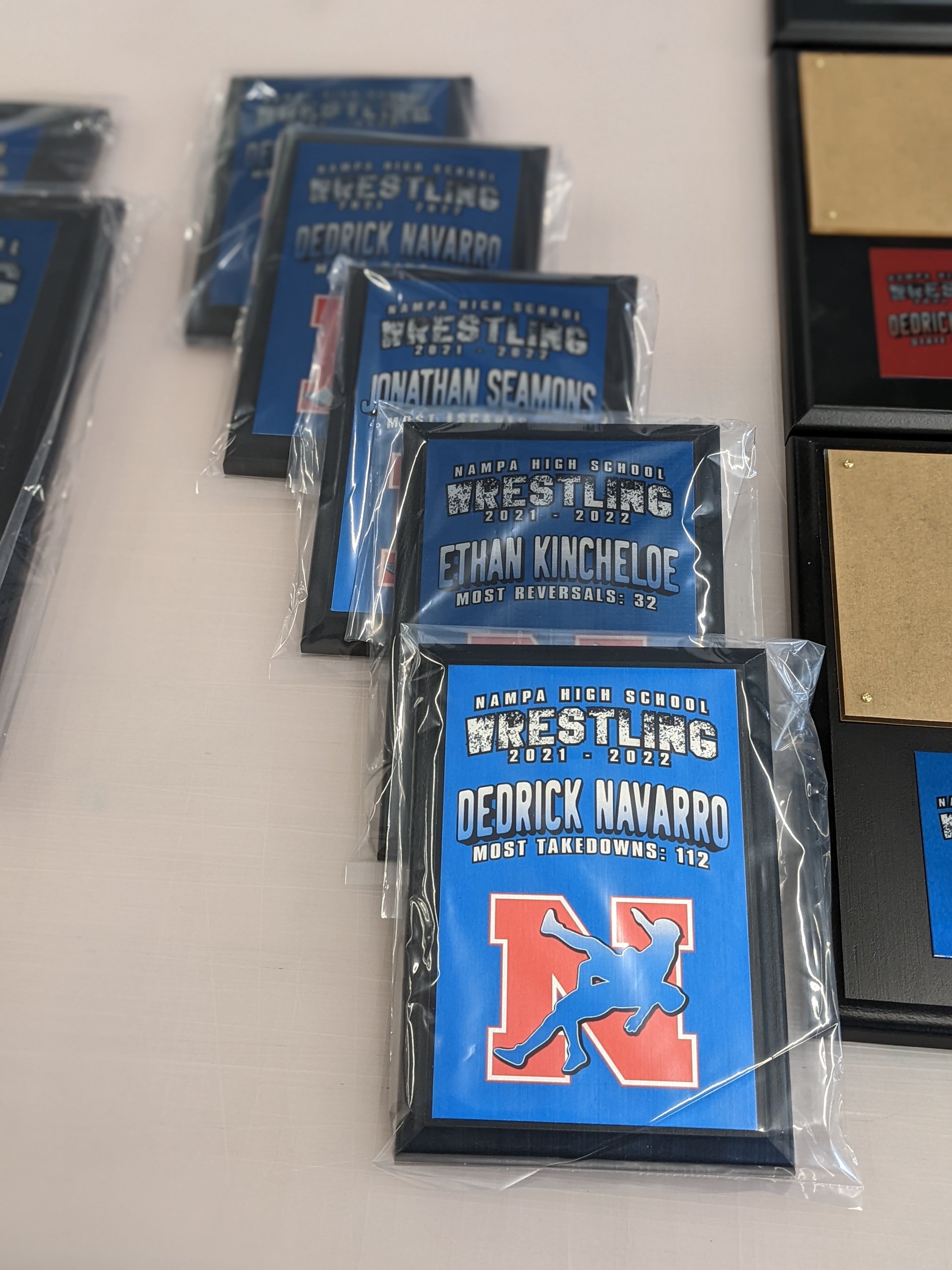

I've also worked with small-format sublimation for plaques, awards, and name badges - I enjoy seeing the color on silver sublimation aluminum because of the subtle brush effect and shine from the aluminum coloring.

Simulation (I just stuck one on top of another lamp)

Gluing together the bottoms

Here's how it hangs from a bulb

I used this lamp for inspiration. My partner and I took a class at the Maker Shop in Boise and learned to make this pattern with hand tools. These are both hand made by us!

My first multi-part project with the laser engraver was a set of three lamps. Each panel is 7x7 inches, and the edges were intended to lock together to make a box. I learned rather quickly that I had the wrong laser cutter for this project; I used a galvo-style laser and the edges of each square were beveled away from the center, causing issues when fitting this together.

I also used some plywood that ended up cupping in various directions - make sure to use the flattest stock possible!

The paper is a mulberry paper that has been glued to the inside,.